PIPELINE

APG NEWSLETTER

Since 1990, our monthly Pipeline newsletter has been delivering important updates and insights to both employees and vendors at APG. Each issue highlights company news, project updates, and other valuable information to keep everyone connected and informed.

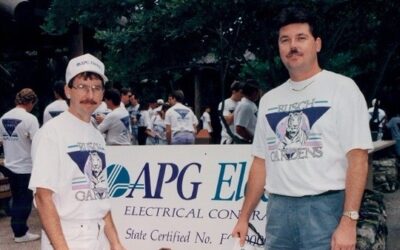

DECADES OF DEDICATION – Thank You, Terry Ryan

APG|Feb 1, 2026| Pipeline News

After nearly four decades of dedicated service, APG proudly celebrates the retirement of Terry Ryan, whose career has left a lasting mark on our company, our people, and the projects that define our legacy. Terry joined APG in September 1986, beginning his career in the field before moving into...

BUILDING ON SUCCESS – Recapping 2025 and Looking Ahead to 2026

APG|Jan 1, 2026| Pipeline News

Now that 2025 has come to a close, we look back on an extraordinary year for APG. The Tampa Bay construction market continues to surge with opportunity, creating stronger wages, better benefits, and improved working conditions for those in the trades. With that growth has come a year filled with...

UNIVERSALLY FUN! – The 41st Annual APG Family Picnic

APG|Dec 1, 2025| Pipeline News

The APG family came together for another unforgettable day of fun at our 41st Annual Family Picnic, held at Universal Studios Florida™ and Universal’s Islands of Adventure™! Employees and their families arrived throughout the morning, excited to spend the day exploring both parks with their...

GOLF ON A NEW LEVEL – 5th Annual APG Employee Golf Tournament

APG|Nov 1, 2025| Pipeline News

On Saturday, October 11, APG held its 5th Annual Employee Appreciation Golf Tournament at Topgolf St. Petersburg in Carillon. The event featured seven bays with four players each, creating an afternoon of friendly competition and camaraderie. Each bay crowned its own champion, while all...

BUILDING A CENTER OF HOPE – Moffitt Speros FL

APG|Oct 1, 2025| Pipeline News

Moffitt Cancer Center is embarking on its largest expansion to date with the creation of Speros FL, a 775-acre global innovation center in Pasco County. Derived from the Latin word sperare, meaning “to hope,” the campus reflects Moffitt’s mission to expand access to care and advance the fight...

PRECISION MEETS POWER – USF MDC Building Upgrade

APG|Sep 1, 2025| Pipeline News

Over the past year, the APG team has been hard at work on a complex and challenging project at the University of South Florida (USF) in Tampa — specifically at the MDC Building, a vital research facility. This building houses decades of valuable scientific biological samples stored in highly...

BUILDING TOMORROW, TODAY – APG Prefabrication Facility

APG|Aug 1, 2025| Pipeline News

We are excited to announce the opening of our new Prefabrication Facility, a major step forward in our commitment to innovation, efficiency, and quality. Located in Tampa, this 11,250-square-foot facility officially opened its doors on April 1, 2025, and will serve as the backbone of our growing...

A NIGHT TO REMEMBER – APG Annual Awards Party

APG|Jul 1, 2025| Pipeline News

On Saturday, June 7, APG employees and their spouses gathered at the beautiful Ruth Eckerd Hall in Clearwater to celebrate the 2024 safety year and recognize the dedication, achievements, and milestones of our team. This event is one of our favorite annual traditions—bringing together the APG...

EXCELLENCE IN FOCUS – APG Wins Top Honors At ABC Awards Gala

APG|Jun 1, 2025| Pipeline News

The Hilton Tampa Downtown Hotel was filled with industry leaders on May 2nd for the Associated Builders and Contractors (ABC) Florida Gulf Coast Chapter’s 2025 Excellence in Construction Awards Gala. This prestigious program celebrates the finest work completed by ABC members over the past two...

PROJECT SPOTLIGHT – Opal Sol Hotel

APG|May 1, 2025| Pipeline News

Rising along the Clearwater Beach shoreline, the newly completed Opal Sol Hotel is a stunning addition to the Gulf Coast horizon. This 15-story, 248-room luxury resort boasts spectacular waterfront views and top-tier amenities, including a pool deck terrace, nine-level parking garage, multiple...

CONTINUED EXCELLENCE – APG Wins Two IEC Awards

APG|Apr 1, 2025| Pipeline News

We are thrilled to announce that APG has been honored with two prestigious IEC National Awards for Excellence in Electrical Construction! These awards recognize our team’s expertise and commitment to delivering top-tier electrical installations, spanning both ends of the commercial construction...

PROJECT UPDATE – Tampa General Hospital

APG|Mar 1, 2025| Pipeline News

Tampa General Hospital’s future is taking shape, and APG is proud to play a pivotal role in bringing it to life as a key contractor on the new TGH Taneja Surgical, Neuroscience and Transplant Tower. This 13-story, 563,000-square-foot facility is designed to set a new standard for patient care. The...

Corporate Headquarters

4825 140th Ave N,

Clearwater, FL 33762

info@www.apg.company

727.530.0077

© 2021 APG. All Rights Reserved. | Terms of Use